Cummins 5.9L and 6.7L cylinder heads have integral cast intake manifolds that create problems for all out performance head configuration. The only way to access all the intake port angles is to remove the cast manifold area and machine the surfaces for an aftermarket intake system. Once this is done, the entire intake side of the cylinder head is accessible for re-working and modifying to suit the engine builder.

This view to the right shows the stock intake removed and the CNC mill setup after drilling and tapping for the aftermarket intake manifold mountings.

This view to the right shows an aftermarket intake manifold positioned to check the mounting machine work already performed.

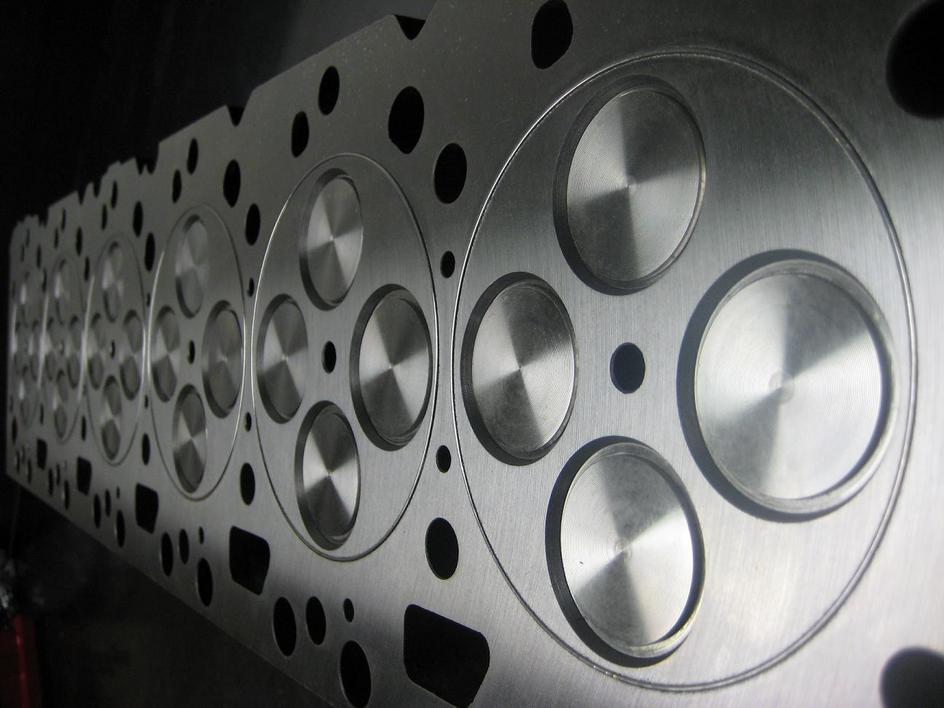

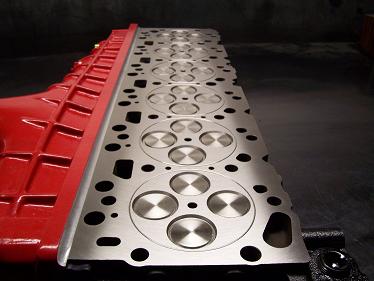

This view clearly shows the improved access to the intake ports and runners attained by removing the cast manifold. This allows port work to be performed.

The view to the right shows our finished product. This is a 2008 6.7L cylinder head that has been fitted with our Race Performance oversize valves and seats, CNC and hand ported, and fit with an aftermarket manifold. The head has been decked, valve recession corrected, and fire ringed. The flow bench results indicated a 44% flow increase for the exhausts, and an average of 36% increase for cylinders 1-5, and 47% on #6 cylinder.

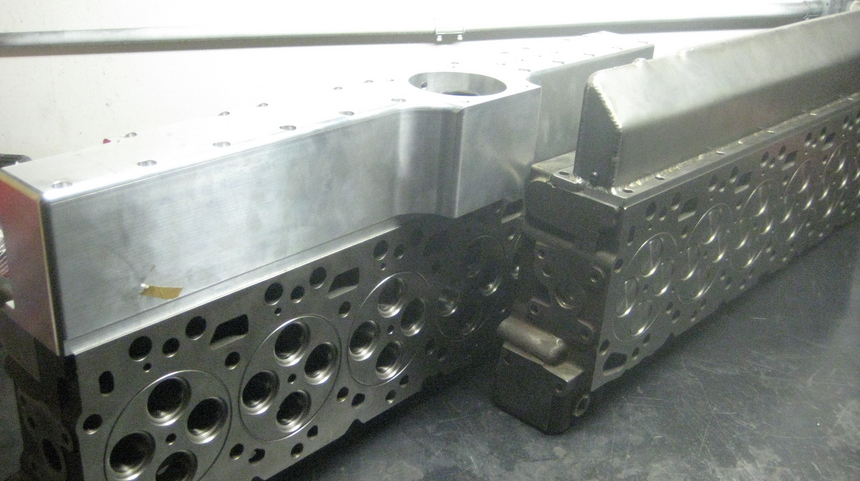

This view to the right shows two different style aftermarket intakes. One is an aluminum side entrance manifold, and the other, a steel top entrance manifold that utilizes the stock intake plate for installation using all stock components. These represent two good examples of the ever growing aftermarket availability of Cummins engine upgrades.

This view to the right shows two different style aftermarket intakes. One is an aluminum side entrance manifold, and the other, a steel top entrance manifold that utilizes the stock intake plate for installation using all stock components. These represent two good examples of the ever growing aftermarket availability of Cummins engine upgrades.

Double click here to edit this text.